Are Your Guitar Tuning Pegs Hard to Turn? (How to Fix Them)

Tuning your guitar is a relatively easy task once you have a little experience, but if your tuning pegs are stiff and hard to turn it makes tuning much harder.

There are a few reasons why guitar tuning pegs get hard to turn, and usually it comes down to a combination of dirt, corrosion, age, and humidity. You can lubricate open-style tuners which can help, but other tuners are not so obvious to fix.

Rather than buying a set of new tuners for your guitar, there are a few things you can do at home to free up your tuning pegs, and make tuning your guitar much easier.

How Hard to Turn Should Tuners Be On Your Guitar?

Guitar tuning pegs (also known as machine heads), need to have some degree of resistance when you turn them. This small amount of friction is what keeps them from unwinding with the strings pulling on them.

Even with this resistance, tuning pegs should be quite easy to turn even for children. Once they become too tight it can be very hard to tune your guitar accurately, and can become really frustrating.

If the tuners on your guitar are tighter than you are comfortable with, then it’s time to do something about it.

Here are the three common types of tuning pegs, and I’ll go through some steps that will help you free up their movement.

1. Open-style Geared Tuners

Side-mounted Classical Guitar Tuning Pegs

This type of tuner is only found on nylon string guitars, and are not suitable for the higher tension of steel strings.

Since the gears are open they tend to attract dust, and can also corrode (rust) which makes them very hard to turn.

Problem 1: The Post Retaining Hooks

Usually each tuning post is held onto a metal plate with hooks bent out and over the shaft of the peg. With older tuners these metal retaining hooks can bend upward, causing the gears to get out of alignment.

If you remove the string tension from the post and the tuning post can wobble around, then the hooks need to be bent down again to hold the post in place properly.

Problem 2: Dirt & Dust

With dirty gears and posts you get a lot of extra friction making the post very hard to turn.

It’s best to use an old toothbrush, some naptha, and a soft cloth to clean them first. The toothbrush will let you clean deeply into the gears, and around the post where it rotates in the retaining hooks.

Problem 3: Corrosion (rust)

If your tuners have become corroded then the surface of the metal is likely damaged, and at this point the best option is to replace the tuners.

If you’re a die-hard DIY fan or don’t want to replace the tuners, then first you will need to dismantle the gears from the shaft with a screwdriver.

Then grab some metal polish and use your trusty toothbrush to work it around anything metal, and then rub dry with a soft cloth.

Lubricating the Tuners

After cleaning, you need to add some lubricant. You can use a cotton bud with a small amount of silicon oil, but note that the oil can cause dust to stick again in the future.

Graphite powder is a good lubricant (but a bit messy), or just get a lead pencil and work the tip around the gears and post contact points. Otherwise use some PTFE teflon spray lubricant which doesn’t attract dust since the surface remains dry.

Move the tuner back and forth a few times without string tension to get the lubricant to coat all the surfaces.

Rear-mounted Vintage Tuners

These are identical to side mounted tuners in the way they work, except many of them are individually screwed to the guitar.

Since they work the same way, just use the same methods as the side mounted tuners.

2. Covered Tuners

Vintage Kluson and Modern Covered Tuners

Kluson-style tuners were used for many years on guitars, and still are today for a vintage look and also for a lightweight tuning peg that doesn’t add much weight to the neck.

They work in the same manner as open gear tuners, except the cover helps to keep dust and dirt out. The downside is that on many of these tuners you can’t remove the back without bending the metal.

This limits how much you can do to fix them, but as long as they are mechanically working without too much free-play you can still improve their ease of turning.

Cleaning Covered Tuners

Since you can’t get inside them to clean manually, the best thing you can do is soak them in some naphtha or denatured ethanol for a few hours.

To help remove particles, turn the post back and forth a few times with the button and swoosh them around in the liquid.

Some of the cheaper modern covered tuners have backs that can be removed after you unscrew them from your guitar. For these, just clean them up and lubricate them using the same methods as for the uncovered tuners.

Lubricating Covered Tuners

Let your tuners dry well before adding some lubricant back into them. There is a small hole in the housing for adding lubricant, and you can add a few drops of silicon oil, or teflon lubricant (such as Super Lube).

3. Sealed Machine Tuners

Sealed tuners have a tighter tolerance than other tuners, and sometimes they can be hard to turn if they are not adjusted properly.

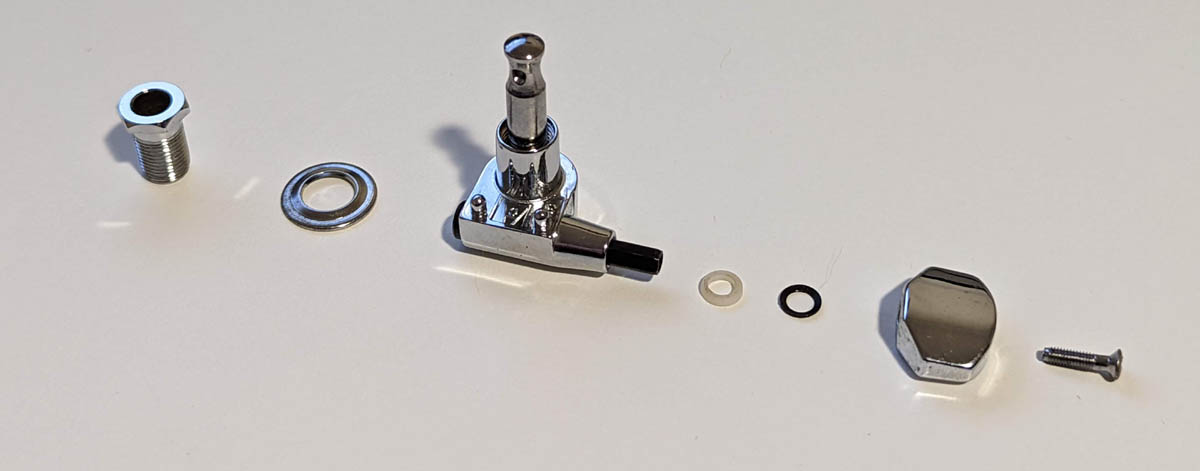

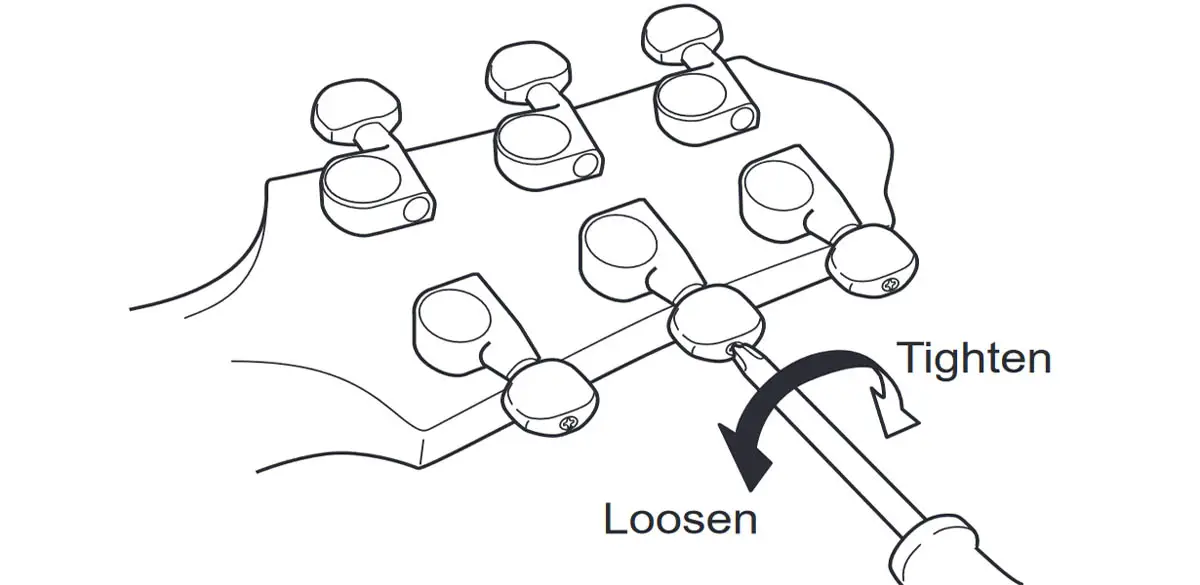

If they feel too tight, try loosening the screw holding the button on, but just by ¼ turn. If this makes the tuning post easier to turn without any extra wobble in the shaft, then your job is done.

You can also take the button off, and add a little lubricant around the two washers under the button, this will help it turn easier (check the video below).

If the button trick doesn’t work, then you will need to take the tuners apart to add some lubricant.

Some sealed tuners are easy to get the cap off the bottom, and this exposes the gear which you can then lube. Others you can remove the button and the post will slide part way out, letting you get some silicone lubricant or vaseline into the gear.

For machine heads that you can’t open, you may be able to put a little vaseline down the sides of the shaft, and heat them with a hairdryer to get the vaseline to run down inside.

Tuning Posts That Won’t Turn

Sometimes the gears can shear-off a tooth, and the broken metal will stop the gear from turning.

For open tuners, just inspect the teeth to see if any are broken, as this can cause the tuner to slip at one spot, and you will need to replace your tuners.

Sealed tuners will get the broken tooth stuck inside, and may jam up completely.